5. Mar. 2025

The research team consisting of Michaela Remešová, Lenka Klakurková and Vendula Bednaříková, all members of the High-Performance Materials and Coatings for Industry (HPMC4I) research group, led by Ladislav Čelko at CEITEC Brno University of Technology, contributed significantly to the successful completion of the TAČR project FW03010160. The project aimed to develop an electrochemical polishing technology for additively manufactured parts made from 316SS and AlSi10Mg. The technology addresses existing shortcomings in additive manufacturing and has potential applications in a range of fields, from medicine to space applications. The technology was awarded the Chairman's Gold Medal at the International Engineering Fair in Brno.

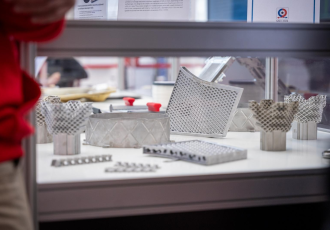

Additive manufacturing, also known as 3D printing, is a process in which three-dimensional objects are created by gradually adding material layer by layer, following a digital model. Unlike traditional manufacturing methods, such as machining or casting, where the material is removed or cast into a mould, additive manufacturing allows for the production of objects with complex shapes that would be difficult to achieve using conventional processes.

The developed technology solves one of the key disadvantages of the additive manufacturing of metal parts, which is the resulting surface quality (roughness). This property hinders the practical use of additively manufactured metal parts, especially in areas such as space applications. The current surface quality of additively manufactured parts largely limits their actual design and the possibilities of using thin-walled and rod structures that would lead to a substantial lightening of the resulting components and optimization of their overall shape for better strength in the desired direction. The use of rod structures in the design of newly developed components thus represents significant potential for further improvements in performance, such as weight reduction, more efficient heat transfer, etc. The developed electrochemical polishing technology can also be used in other fields, for example, in additively manufactured metal biocompatible bone substitutes (implants), where a smoother surface with better interaction with surrounding tissues is achieved by this method, improving the process of tissue ingrowth and also reducing the risk of bacterial contamination. The technology thus opens up new possibilities for the use of additively manufactured aluminium and stainless-steel parts in application areas where such parts have not yet been widely accepted.

The High-Performance Materials and Coatings for Industry research group focuses on various surface treatments, with one area being the use of chemical and electrochemical processes. Recently, we have noticed an increasing demand for surface treatments of 3D printed metal parts, which was, to some extent, the focus of Michaela Remešová's foreign internship within the CLiCAM project. "The internship at a company specializing in 3D metal printing provided us with a comprehensive understanding of the specific needs of customers looking for ways to improve and maximize the performance of their 3D-printed parts. In addition to reducing the surface roughness of 3D-printed parts, there is also a focus on enhancing corrosion resistance or producing insulating coatings (anodic oxidation of aluminium alloy parts). However, due to the specific microstructure of 3D-printed materials, conventional surface treatment processes used for moulded or cast materials in industrial practice are not applicable, requiring the development and implementation of entirely new procedures and technological solutions," Michaela explains.

This technology was developed in collaboration with One3D, CEITEC BUT and the Faculty of Mechanical Engineering BUT and was awarded the prestigious Gold Medal by the chairman of the evaluation committee in the category of Excellent Cooperation in Research and Development between Academia and Industry at last year's International Engineering Fair in Brno.

Share

Share