5. May 2021

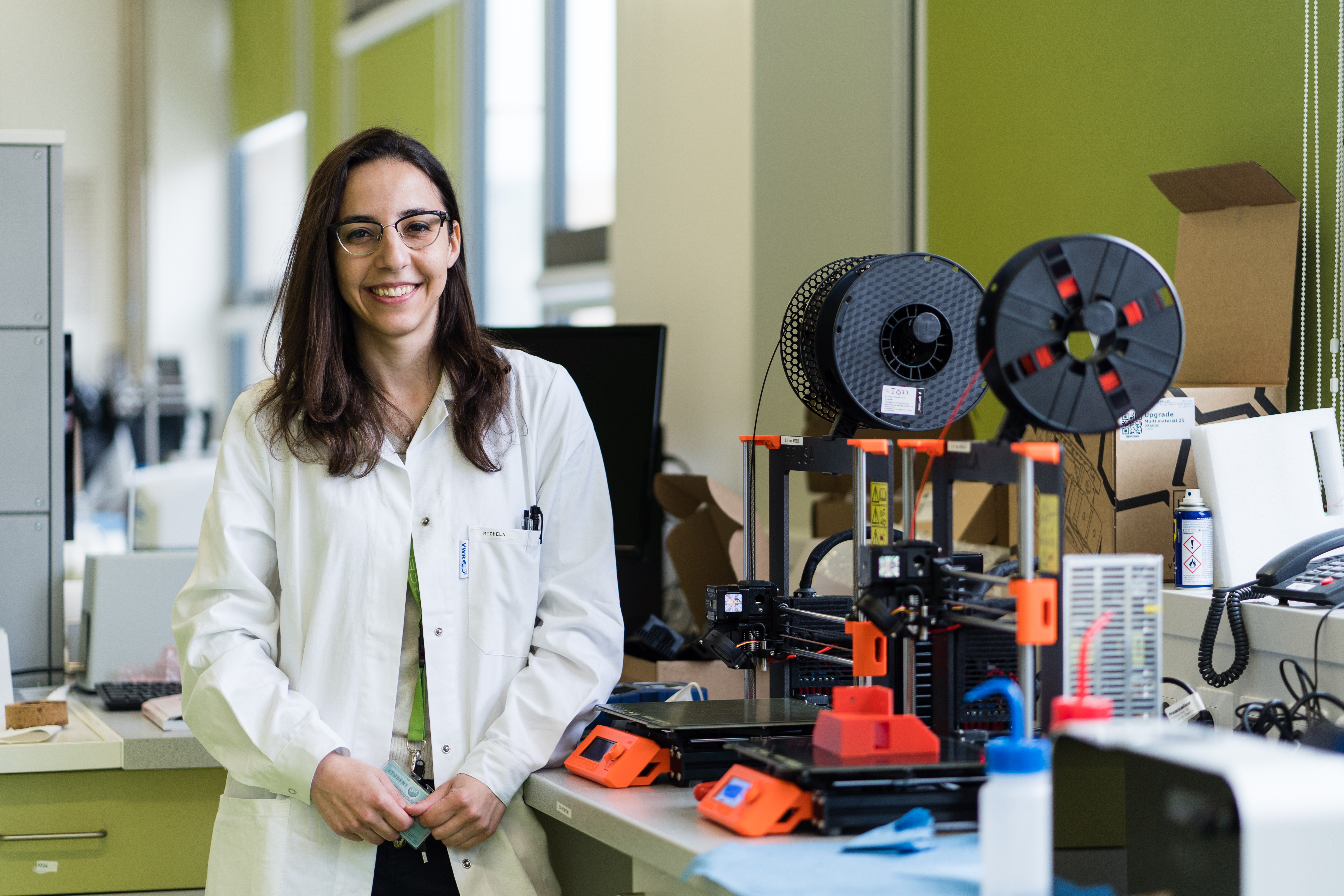

A year ago, right in the middle of the pandemic, Michela Sanna arrived at CEITEC BUT to study her Ph.D. The work in the research group dealing with the future energy, under the leadership of Martin Pumera, was not stopped even by the difficult conditions associated with the coronavirus. For her project, which deals with the electrochemical production of hydrogen, one of the most promising alternatives to fossil fuels, Michela won the Ph.D. Talent Award.

A year ago, right in the middle of the coronavirus pandemic, Michela Sanna arrived at CEITEC BUT to study her Ph.D. The work in the research group dealing with the energies of the future, under the leadership of Martin Pumera, was not prevented even by the difficult conditions associated with the coronavirus. For her project, which deals with the electrochemical production of hydrogen, one of the most promising alternatives to fossil fuels, Michela won the Ph.D. Talent award.

She came research centre in Brno quite by chance. She went to Brno several times to visit her boyfriend, who also works in science. “I was looking for interesting projects here, that I could sign up for, and came across Martin Pumera's group, which I found very interesting,” describes Michela Sanna. Although, the group focuses mainly on the study of new materials and advanced electrochemical energy materials, in Italy Michela focused more on organic chemistry.

The bridge between 3D printing technologies and organic materials

“I like that, I can combine the work with inorganic materials with use my previous experiences in organic chemistry,” says the Ph.D. student. And it was the combination of new materials with organic compounds that she bet on in the award-winning project. “I am planning to combine 3D printing technology and photoactive organic molecules to obtain new electrodes. These electrodes can be used for electrochemical generation of hydrogen from water, with the help of sunlight,” she explains. Today, hydrogen is already produced electrochemically from water with the help of renewable sources, but expensive catalysts are needed. For this reason, today only about 10% of the total hydrogen production is produced using this method. However, most of the world's hydrogen production still comes from fossil fuels.

After 3D printing of the electrodes, it is time for layer´s deposition

By using the 3D printing technique for the production of electrodes, the cost of obtaining hydrogen by electrochemical means could be reduced. “I plan to functionalize the 3D printed electrode, which is a tiny spoon, with photoactive molecules. To do this, I will use the Atomic Layer Deposition (ALD) of inorganic oxides to create a bridge between the electrode and the given organic molecule,” explains Sanna.

She has just finished the preparation of the prototype electrodes and soon, she is going to deposit the inorganic layers. The coronavirus slows down the progress a little bit, mainly due to more complicated deliveries of ordered material.

“I am very happy that despite the complicated situation, I was still able to go to the laboratory. I like working at CEITEC, mainly because the local background and the international research group,” she says. It was the view of people from other scientific backgrounds that she lacked at her alma mater. For this reason, she would like to try working in another country after completing her Ph.D. studies. For the time being, however, she will remain in Brno for a few more years, which is, according to her, an ideal combination of a larger city with an intimate atmosphere.

Autor: Aneta Matysová

Share

Share